The performance of Diversity water device valve depends on both materials and design. These valves must withstand water pressure, resist corrosion, and provide reliable operation over time. Engineers consider factors such as temperature range, chemical exposure, and mechanical stress when selecting materials and designing components.

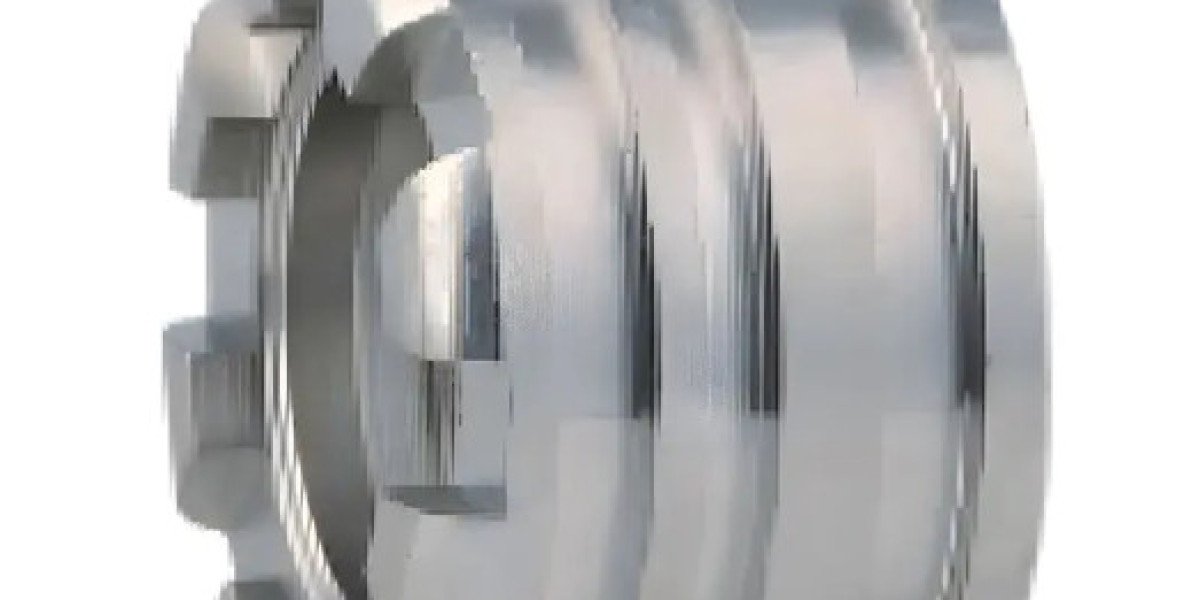

Common materials include brass, stainless steel, and engineered plastics. Brass offers durability and good corrosion resistance for general water systems, while stainless steel is preferred in applications where chemical resistance or higher temperatures are required. Plastic valves are lightweight and resistant to scaling, making them suitable for residential installations or low-pressure systems.

Valve design also influences performance. Some diversity water device valves are equipped with adjustable features, allowing users to fine-tune flow for different outlets. Others incorporate internal chambers that separate flows to prevent backflow or pressure fluctuations. Compact designs help reduce installation space, while modular options make maintenance easier.

Maintenance is essential for longevity. Valves must be periodically inspected for wear, debris, or leaks. Cleaning internal components and replacing worn seals can prevent operational issues and ensure consistent water delivery.

By carefully considering both materials and design, diversity water device valves can provide reliable service across a wide range of applications. Engineers and installers can select appropriate models based on system requirements, environmental conditions, and desired functionality, ensuring effective water management and long-term performance.